Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for OEM/ODM Supplier Du Horizontal Mining Sludge Dewatering Machine Vacuum Rubber Belt Filter Press, We always follow the principle of “Integrity, Efficiency, Innovation and Win-Win business”. Welcome to visit our site and tend not to be reluctant to communicate with us. Are you prepared? ? ? Allow us to go!!!

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for China Dzu Series Filter and Belt Filter Press, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there’s any opportunity, welcome to visit our factory!!!

Product Introduction

ZWN series micro filter adopts 15-20 micron ventage filter process which terms as micro filtering .Micro filtering is a kind of mechanical filtering method .It is applied to maximally separate the micro suspended substance (pulp fiber ) existing in the liquid and realizes separations of the solid and liquid .

Product Parameters

Structure and working principle

This type microfiltration machine is a kind of mechanical filtering machine, consists of transmission device, overflow water distributor, wash water device, filter screen is stainless steel wire mesh. Its working principle is to deal with water from the pipe into the overflow weir, after brief steady flow, by uniform overflow outlet and distribution in reverse direction of cartridge filter, water filter with the cylinder wall shear relative movement, high efficiency water, solids are divided by a river closure, along the cylinder spiral guide plate rolling, the filter tube at the other end. The filtrate is outflow from the tank. Outside the machine filter cylinder is equipped with water pipe, flushing water pressure (3kg/cm squared), and fan injection with flushing dredge mesh, guarantee the mesh remains good filtering capabilities.

Features

1. Modularized design is for easy installation and transportation.

2. High auto degrees: Consecutive auto feeding, filtering, washing, dewatering, discharging, cloth cleaning improves production efficiency.

3. Fast filter speed: large particles will settle at the lower layer while small particles upper layer when material goes through sedimentation area. Reasonable structure of filter cake ensures low resistance of liquid for fast filter of thin layer.

4. Convenient filter technology: cake thickness, water vol., counter current decantation stages, vacuum degree, filter speed can be adjusted for optimistic effect.

5. Fine decantation effect: even and thorough multi-stage advection or counter current decantation makes collection and reuse of mother liquor and washing liquor separately.Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for OEM/ODM Supplier Du Horizontal Mining Sludge Dewatering Machine Vacuum Rubber Belt Filter Press, We always follow the principle of “Integrity, Efficiency, Innovation and Win-Win business”. Welcome to visit our site and tend not to be reluctant to communicate with us. Are you prepared? ? ? Allow us to go!!!

OEM/ODM Supplier China Dzu Series Filter and Belt Filter Press, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there’s any opportunity, welcome to visit our factory!!!

-

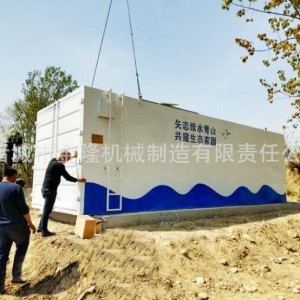

Factory directly 1000lph Sewage Water Treatment...

-

China Wholesale New Technology Marine Sewage Tr...

-

Fast delivery Slaughterhouse Sewage Treatment R...

-

High definition Waste Water Treatment System Fl...

-

OEM/ODM Factory Industrial Sewage Treatment Aut...

-

100% Original Rod Flotation Machine