We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Leading Manufacturer for 24 Hours Automatic Running Sludge Dewatering Machine, We’re not content together with the present achievements but we have been trying greatest to innovate to satisfy buyer’s more personalized needs. No matter where you’re from, we are here to wait for your type ask for, and welcom to visit our manufacturing unit. Choose us, you can meet your reputable supplier.

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for China Filter Press and Press Filter, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products and solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Product Introduction

ZWN series micro filter adopts 15-20 micron ventage filter process which terms as micro filtering .Micro filtering is a kind of mechanical filtering method .It is applied to maximally separate the micro suspended substance (pulp fiber ) existing in the liquid and realizes separations of the solid and liquid .

Product Parameters

Structure and working principle

This type microfiltration machine is a kind of mechanical filtering machine, consists of transmission device, overflow water distributor, wash water device, filter screen is stainless steel wire mesh. Its working principle is to deal with water from the pipe into the overflow weir, after brief steady flow, by uniform overflow outlet and distribution in reverse direction of cartridge filter, water filter with the cylinder wall shear relative movement, high efficiency water, solids are divided by a river closure, along the cylinder spiral guide plate rolling, the filter tube at the other end. The filtrate is outflow from the tank. Outside the machine filter cylinder is equipped with water pipe, flushing water pressure (3kg/cm squared), and fan injection with flushing dredge mesh, guarantee the mesh remains good filtering capabilities.

Features

1. Modularized design is for easy installation and transportation.

2. High auto degrees: Consecutive auto feeding, filtering, washing, dewatering, discharging, cloth cleaning improves production efficiency.

3. Fast filter speed: large particles will settle at the lower layer while small particles upper layer when material goes through sedimentation area. Reasonable structure of filter cake ensures low resistance of liquid for fast filter of thin layer.

4. Convenient filter technology: cake thickness, water vol., counter current decantation stages, vacuum degree, filter speed can be adjusted for optimistic effect.

5. Fine decantation effect: even and thorough multi-stage advection or counter current decantation makes collection and reuse of mother liquor and washing liquor separately.We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Leading Manufacturer for 24 Hours Automatic Running Sludge Dewatering Machine, We’re not content together with the present achievements but we have been trying greatest to innovate to satisfy buyer’s more personalized needs. No matter where you’re from, we are here to wait for your type ask for, and welcom to visit our manufacturing unit. Choose us, you can meet your reputable supplier.

Leading Manufacturer for China Filter Press and Press Filter, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products and solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

-

China Cheap price Hot Sale Rotary Vacuum Filter...

-

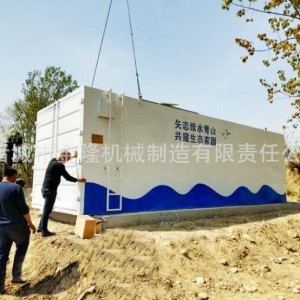

OEM Manufacturer Small Sewage Treatment Plant

-

Hot Selling for Automatic Backwashing Microfilt...

-

OEM Manufacturer Stainless Steel Automatic Dewa...

-

Factory making Wastewater Systems Clarifier Wat...

-

China Wholesale New Technology Marine Sewage Tr...