Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for China Manufacturer for Integrated Sewage Treatment Equipment for Scenic Spot Sewage, Scenic Spot Wastewater, We believe that a passionate, revolutionary and well-trained team should be able to establish great and mutually beneficial business enterprise relationships with you soon. Please truly feel no cost to get hold of us for additional details.

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for China Scenic Spot Sewage and Scenic Spot Wastewater, Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers’ satisfaction is our future!

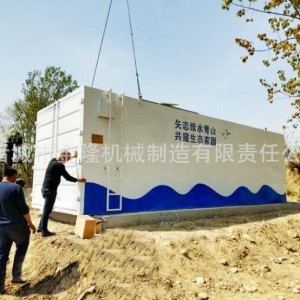

Product Introduction

The level 2 biological contact oxidation process adopts the patent aerator, it doesn’t require complicated pipe fittings. Compared with the activated sludge tank, it has a smaller size and a better adaptability to water quality and stable outlet water quality. No sludge expansion.

The sludge tank adopts the natural sedimentation method, one discharge for sludge is necessary for every three to eight months. (Suck the sludge with dung-cart or carry away after dewatering.)

Generally, specially-assigned person is unnecessary for the device, proper maintenance is needed.

With a strong adaptability to the variation of water quality.

It doesn’t require compression container. The equipped air compressor and circulating pump reduce the investment cost a lot.

With lower power consumption and less maintenance. The aerobic process of this device can purify the stench of sludge.

Advantages

1.Compact structure,small land occupation.

2.One unit with full components,efficient operation.

3.Combine the nucleus and assistant treatment,with stable water quality.

4.Apply qravity flow,saving power.

5.Simple operation,no professional management.

Equipment structure

1. High efficiency biochemistry treating field:apply new type of filler,with large specific surface area,strong adhesive attraction and well attack resistance ability.

2.Settling pond:apply inclind tube settling with high efficiency,small volume of settling pond.

3. Filtering pond:apply light filter material,water power for backwashing,so there is no need of backwashing pump, and it saves electricity.

4. Contact sterilized pond:mixing thimerosal and wastewater to ensure the out water index.

5. All of the system applies integrated treatment as equipment nucleus,assisted pump,blower and thimerosal dosing equipment.

COD removal and sludge yield

Simply due to the high number of microorganism in MBRs, the pollutants uptake rate can be increased. This leads to better degradation in a given time span or to smaller required reactor volumes. In comparison to the conventional activated sludge process (ASP) which typically achieves 95%, COD removal can be increased to 96-99% in MBRs. COD and BOD5 removal are found to increase with MLSS concentration. Above 15g/L COD removal becomes almost independent of biomass concentration at >96%.

Arbitrary high MLSS concentrations are not employed, however, as oxygen transfer is impeded due to higher and Non-Newtonian fluid viscosity. Kinetics may also differ due to easier substrate access. In ASP, flocs may reach several 100 μm in size. This means that the substrate can reach the active sites only by diffusion which causes an additional resistance and limits the overall reaction rate (diffusion controlled). Hydrodynamic stress in MBRs reduces floc size (to 3.5 μm in sidestream MBRs) and thereby increases the apparent reaction rate. Like in the conventional ASP, sludge yield is decreased at higher SRT or biomass concentration. Little or no sludge is produced at sludge loading rates of 0.01 kgCOD/(kgMLSS d).Due to the biomass concentration limit imposed, such low loading rates would result in enormous tank sizes or long HRTs in conventional ASP.

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for China Manufacturer for Integrated Sewage Treatment Equipment for Scenic Spot Sewage, Scenic Spot Wastewater, We believe that a passionate, revolutionary and well-trained team should be able to establish great and mutually beneficial business enterprise relationships with you soon. Please truly feel no cost to get hold of us for additional details.

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for China Manufacturer for Integrated Sewage Treatment Equipment for Scenic Spot Sewage, Scenic Spot Wastewater, We believe that a passionate, revolutionary and well-trained team should be able to establish great and mutually beneficial business enterprise relationships with you soon. Please truly feel no cost to get hold of us for additional details.

China Manufacturer for China Scenic Spot Sewage and Scenic Spot Wastewater, Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers’ satisfaction is our future!

-

Best quality Lsp Two Year Warranty Plastic Recy...

-

Hot New Products Blx Customized Low Temperature...

-

Manufacturer of Top Quality Cow Dung Dewatering...

-

Best quality China Slaughter Industrial Wastewa...

-

Stainless Steel Rotating Drum Filter Screening ...

-

Hot Selling for Automatic Backwashing Microfilt...